Industrial dust extraction

Industrial extraction through modern filter and extraction systems

Quickly and safely extract toxic dusts such as smoke, fine dust, oil mist, vapors, chips, etc. when grinding or welding

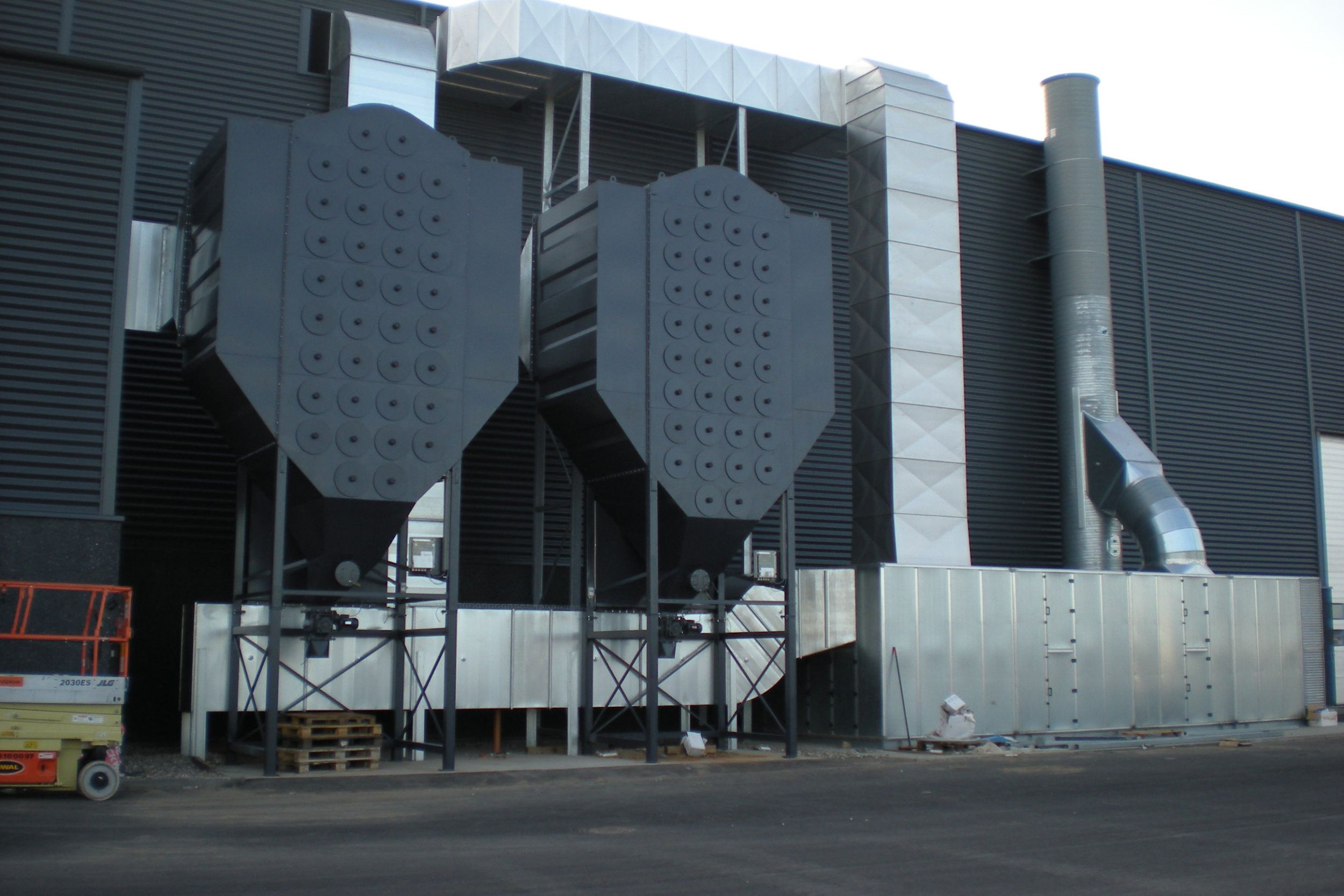

VALCO GmbH -Entstaubungstechnik- deals with problem solutions of industrial dust extraction. We have more than 30 years of experience in this field. We supply and install central vacuum cleaning systems in steel and stainless steel design for almost all industrial sectors. VALCO offers modern industrial extraction with high efficiency. In recent years, we have specialized in the development of individually adapted extraction systems as well as a wide standard program within the industrial filtration in Germany and Europe. This is usually done in close cooperation with our customers. The dust extraction systems are made of tested basic elements adapted to the individual processes.

Customized dedusting systems from the manufacturer

VALCO Entstaubungstechnik has extensive process knowledge, which is necessary to work out solutions to problems and design your individual extraction system. Not only standard systems but especially extraction systems manufactured especially for the customer are convincing in terms of functionality and economy. With over 50 dust extraction systems for BMW AG alone, for the metal and plastics sectors, VALCO GmbH Entstaubungstechnik is one of the leading manufacturers of customized industrial extraction systems in dust extraction technology for almost all industrial sectors.

Dust extraction through modern filters & extraction systems

The project planning and design of an air handling dust collection system for air pollution control requires extensive experience and competence of a specialist. Investment and subsequent operating costs are significantly influenced by factors such as air volumes and the right filter technology.

Possible applications of VALCO filter and extraction systems

Dust

Oil mist

Emulsion mist

Exhaust gases

Chips

Sandblasting

Smoke

Soldering fumes

Metal

Welding fumes

Grinding dust

Carbon dust

Fine dust

Paint

Paint mist

Vapors

Industrial dust extraction: VALCO manufactures the right dust extraction system for every workplace

If you are looking for a professional dust extraction system or a special industrial extraction system, VALCO is the right partner for a custom-fit system. We have been planning and building flexibly adapted systems for industrial extraction for more than 30 years. VALCO is one of the leading manufacturers for a tailor-made dust extraction system for almost all industrial sectors.

Each dust extraction system from VALCO is manufactured in high industrial quality. Our units for industrial extraction are in use in almost every relevant industry worldwide. During the planning process for your dust extraction system, we coordinate closely with you. Industrial extraction with VALCO is efficient and safe.

The construction of a dust extraction system for industrial extraction requires the highest level of expertise

Whenever a dust extraction system is used, safety is also a concern. In the field of industrial extraction, there is a wide range of substances and types of dust that need to be filtered out of the air safely and effectively. These can be free-flowing dusts from the pharmaceutical industry, but also, for example, fine dust, oil mist, soldering fumes or grinding chips. The construction of such a dust extraction system requires the highest level of expertise and, in the best case, experience. VALCO has been active in the field of industrial extraction for more than 30 years and has an exceptionally wide range of products in the field of dust extraction equipment.

The VALCO product groups in the field of industrial extraction:

- Cartridge filters:

suitable for almost all production processes in the industrial sector - Bag filter:

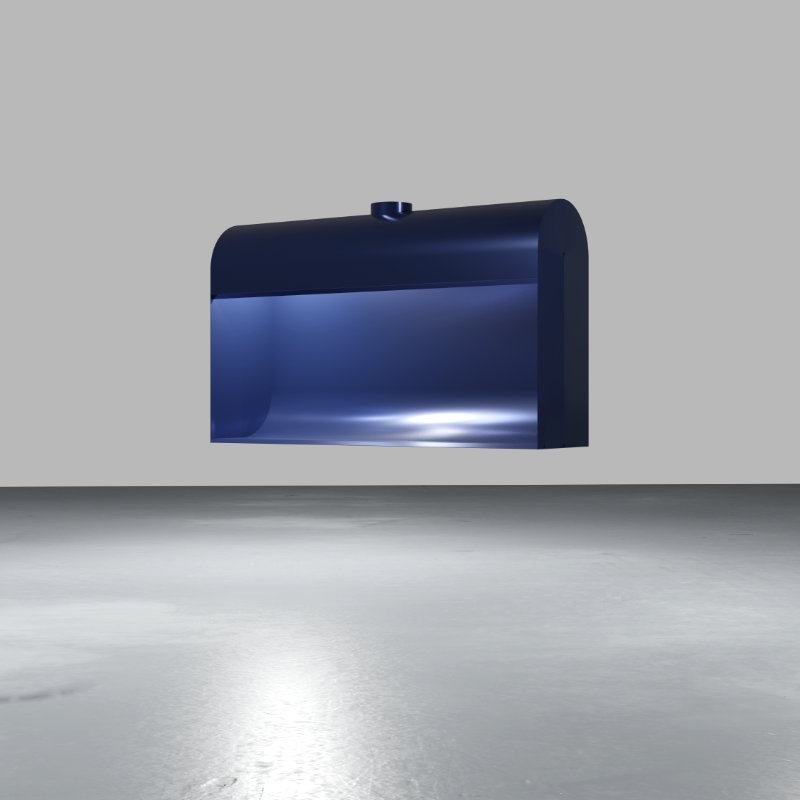

especially used for dusts that are difficult to clean off, pleated bags with more filter area on request - Oil mist separator:

with multi-stage filtration on request also for recirculating air operation - Central dust extraction system:

ideal for industrial dust extraction in ceramic plants, foundries and in food production, wide range of adaptation possibilities of the dust extraction system due to many different construction types - Mobile filter systems:

Ideal wherever industrial extraction has to adapt flexibly to the task at hand - Explosion-proof filter systems:

Dust extraction system for indoor and outdoor use available in various designs - Extraction hoods for dust and fumes:

Extraction hoods or sinks made of sheet steel or e.g. whirlwind hoods with straight or curved back wall, especially suitable for welding and grinding work

- Extraction tables:

in the field of industrial extraction, particularly suitable for grinding and welding work, large-area dust collection at individual workstations, can be supplied with connections for a central filter system or with integrated filter technology and fan - Flame cutting tables:

for flame cutting systems and plasma cutting systems, this type of industrial exhaust system effectively extracts gases and dust, durable mechanics, proven for rough everyday industrial use, available in standard dimensions or as individual design - Extraction arms:

precisely extracts dust, steam, smoke and chips, numerous accessories available - Fire protection:

VDS approved spark extinguishing system with CO2 or water extinguishing - Fans:

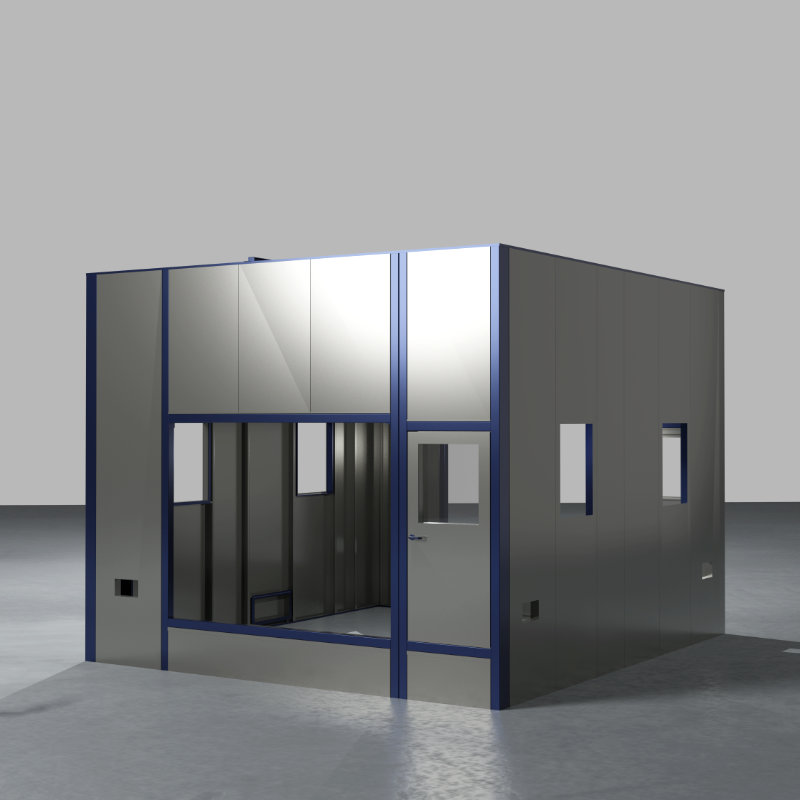

designed and calculated according to the latest findings in fluid mechanics - Soundproof cabins with exhaust system:

Closed and open working cabins, on request with possibility of crane loading

Quality and tested safety of the filtration equipment

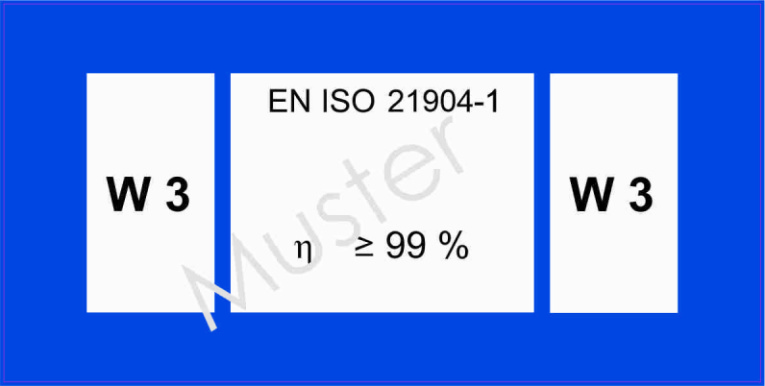

The fully welded construction of our filter units made of 3 millimeter thick sheet steel guarantees optimum tightness and stability for many years. Our cartridge filters comply with the international standard DIN EN ISO 15012-1 (occupational health and safety in welding and allied processes) without testing or individual approval and are marked with welding fume class W3 in accordance with the standard. About the VALCO certificates.

All filter units can be offered as special or ATEX versions for explosive dusts.

ISO 9001 certified

W3 test mark

How high quality are VALCO's filter systems?

With each filter system for industrial exhaust from our production you buy a piece of active and passive safety for your company and your employees. We always manufacture strictly according to the European Health and Safety Directive (2003/10/EC) as well as the wishes and specifications of our customers. If you still have questions, do not hesitate to ask us.

Is it possible to modernize an existing extraction system?

Talk to us, we will be happy to show you how you can optimally modernize your extraction system. We often have particularly inexpensive, efficient and practical solutions to problems and can help with questions of funding opportunities. Trust us and our experience. We offer you our entire expertise and a portfolio from numerous successful projects.

What does the VALCO after-sales service look like?

We do not leave you alone after the purchase. In addition to a comprehensive planning and installation service, we are also always available for after-sales. Adjustments, extensions or repairs can be carried out on your VALCO filter system at any time. Feel free to contact us!

Products

From filtration systems to capture elements, our products cover almost every extraction requirement. In addition, we also offer all systems explosion-proof, with fire protection or in stainless steel design.

Filter systems

Collecting elements

Accessories

Contact

For questions and advice, please feel free to contact VALCO Customer Service. You can reach us by phone or write us an e-mail with the requirement profile for your dust collector. You can also contact a VALCO representative directly.