Hand suction MAPAS

The economical point extraction on the burner

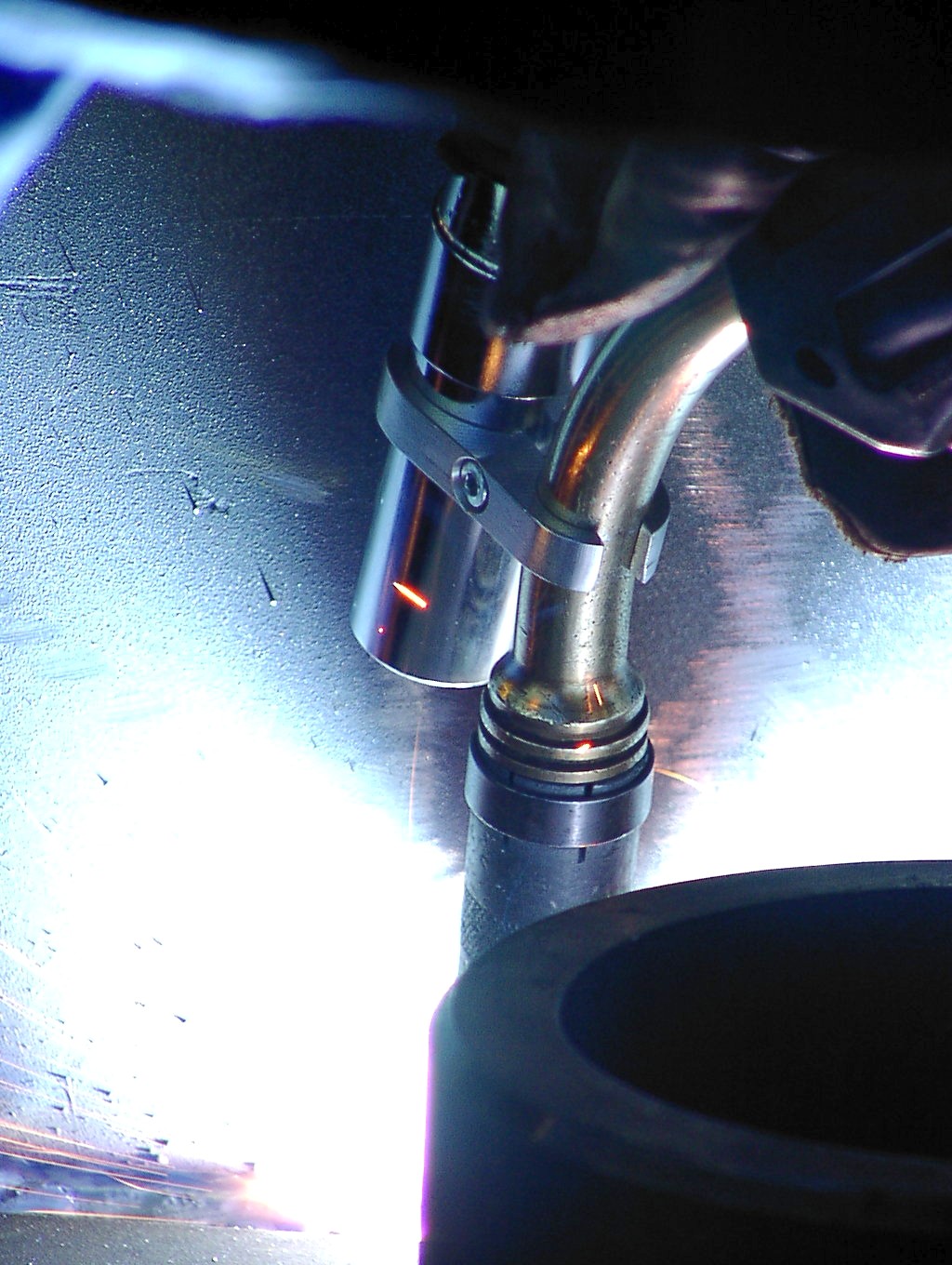

Based on ROPAS, the spot extraction system, which has been used with great success on robots and automatic welding machines since 1992, we have developed a simple, analogous system for manual gas-shielded welding: MAPAS.

Welding fume extraction during manual welding can be taken care of by many detection elements. There are extraction tables, hoods, extraction arms or even point extraction directly at the torch.

However, for complex or even more voluminous components, only a few detection elements are still shortlisted. components, however, only a few acquisition elements are still shortlisted. In the case of extraction arms, it must be noted in practice that these can get in the way with large workpieces or also have to be tracked in the case of complex welding processes. If the welder is to perform this additional operation in the long run, “fatigue” inevitably sets in sooner or later, so that the suction arm is positioned somewhere, but not where it would be effective. Long seams have to be interrupted to track the suction, which actually has a negative effect on weld quality.

Here, the detection directly at the burner provides a remedy! The MAPAS system can be retrofitted to any MIG/MAG shielding gas torch and provide optimum fume collection without having to exhaust the shielding gas as well.

Structure of the MAPAS system:

The system essentially consists of matched parts, in the form of curved pipes, bends, holders and hoses in various diameters, which can be retrofitted as a modular system to any inert gas torch. The high vacuum is generated by mobile devices up to stationary systems, which supply entire halls with vacuum. For the separation of the extracted smoke, high-quality polyester cartridge filters are basically used, which are automatically cleaned even in the simplest mobile device for a workplace.

The advantages at a glance:

Easy-to-use, modular, low-cost system

Very good smoke detection

Can be retrofitted to burners from a wide range of manufacturers

Low cleaning and maintenance requirements

MAPAS variants

We offer our MAPAS system in different versions, so that the optimal solution for your application is used.

CLASSIC:

At welding currents below 300 A, the MAPAS Classic extraction nozzle delivers excellent extraction results. At the same time, the hose packages are light and flexible.

CLASSIC XL:

For welding currents of more than 300 A and welding applications with a high incidence of smoke, the MAPAS Classic XL extraction nozzle delivers excellent extraction results.

REMOVE:

The MAPAS CLASSIC suction nozzle system provides faithful service in many operations. Nevertheless, there is always the desire to be able to quickly remove the nozzle in critical situations. Here is our solution: MAPAS REMOVE

REMOVE XL:

For welding currents of more than 300 A and welding applications with a high level of smoke, the MAPAS REMOVE XL extraction nozzle provides excellent extraction results while offering the possibility to quickly remove the nozzle.

FLEX:

MAPAS FLEX is a brand new retrofittable extraction system for shielding gas welding guns. It provides concentrated suction where the welding smoke rises, namely on the back of the torch bend.

Video demonstration:

Which hand torches can be retrofitted?

All commercially available MIG/MAG inert gas torches can be retrofitted.

The MAPAS system is successfully used on burners from Binzel, Dinse, Cloos, TBI and many other manufacturers.

Is there also a spot extraction for welding robots and automatic machines?

Yes! Our ROPAS system, which was specially developed for welding robots, has been proven for over 20 years and offers great advantages. Learn more here.

Engineering of complete plants

Tailored to your specific requirements

Contact

For questions and advice, please feel free to contact VALCO Customer Service. You can reach us by phone or write us an e-mail with the requirement profile for your dust collector. You can also contact a VALCO representative directly.