Extraction hoods

Optimal large area suction

Our sheet steel extraction hoods ensure optimum removal of all emissions in a wide range of machining processes. We adapt our three types of extraction hoods for robotic use, for circular booth grinding/welding/cutting and with whirlwind extraction individually to the respective task in the operational process.

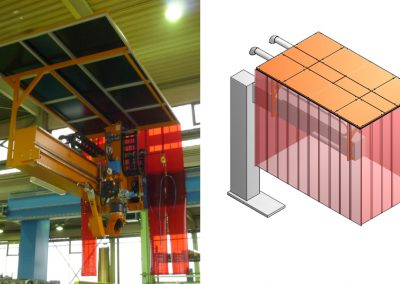

Robotor suction hoods

For automated processes

VALCO has been manufacturing extraction hoods for automated work processes for many years. Our robot exhaust hoods are made of welded steel sheets in galvanized or painted finish and can be ordered with single-flow nozzles and baffles on request. For optimal capture of smoke and dust, we offer the possibility of additionally suspending the sides with slats.

What are the challenges of smoke extraction for robotic operation?

Welding robots require a large radius of movement, which poses a problem for the use of conventional extraction hoods: Spot extraction is hardly possible and the extraction effect of conventional technology decreases too much after a few centimeters distance.

Our solution: Capture the smoke at robot workstations over as large an area as possible. Due to the hot air movement during welding, it is sufficient to extract the smoke above the robot. Lateral suction elements are only required here in the event of cross-flow in the working area.

Sheet steel extraction hoods

Straight or curved back wall

Galvanized or painted

Extraction of smoke, dust

On request with inlet nozzles and baffles

Round cabins

Extraction hoods for round booths for grinding, welding and cutting.

We are also happy to manufacture custom products according to your specifications. For example, the extraction hoods for circular booths for grinding, welding and cutting.

The suction hood shown in the picture functions as a co-rotating grinding and welding booth for round components.

Adapted to your task as a special design, extraction elements from VALCO impress with their clean processing and precise functions. Special designs of extraction hoods as well as standard housings are available from us made of galvanized sheet steel or with a painted surface. According to your requirements we manufacture extraction hoods with manual or electric drive.

Grinding work

Welding work

Cutting work

Whirlwind Hoods

For effective extraction in the working area

We manufacture whirlwind hoods from VALCO made of sheet steel with curved or straight back wall. The whirlwind exhaust hoods are powder-coated according to RAL or can be made of stainless steel on request. Widths are possible from 750 mm to 6,000 mm. The whirlwind hood is equipped with an internal swirl tube. The inflow runs parallel to the longitudinal axis of the suction hood. The end faces of the suction hood are closed including the cylinder part.

How does a whirlwind hood work?

Due to the two opposing suction surfaces (swirl tube) in the suction hood, a vortex is created with a small amount of air, resulting in uniform collection over the entire hood opening.

Swirl tube lying inside

Straight or curved back wall

Powder-coated sheet steel or stainless steel version

Closed end faces

Uniform detection via hood opening

From 750 mm to 6,000 mm width

What are the health hazards of smoke and dust?

In addition to welding fumes, toxic and/or carcinogenic gases can also be generated during welding work, such as ozone, carbon monoxide or nitrous gases (NO, NO2 ,NOX) or hydrogen chloride during brazing and other hazardous substances.

Inhaled grinding dusts may cause skin irritation, sensitization, eye irritation and respiratory diseases.

If hazardous emissions cannot be avoided by technical process modifications, the dust must be completely collected at the point of origin, extracted and safely removed from the work area. (see TRGS)

Why do customers choose VALCO products?

VALCO – when experience counts

If you are looking for a manufacturer who brings experience, quality awareness and customer proximity, then you have come to the right place. VALCO is a leading manufacturer of equipment for industrial extraction and has been producing equipment of the highest quality for 34 years. Trust our know-how and experience in demand-optimized solutions. With us, you don’t get an “off the shelf” extraction hood, but products that have been designed for maximum efficient use.

What does the VALCO after-sales service look like?

We do not leave you alone after the purchase. In addition to a comprehensive planning and installation service, we are also always available for after-sales. Adjustments, extensions or repairs can be carried out on your extraction hood at any time. As a specialist company for special constructions, we are always at the cutting edge.

Engineering of complete plants

Tailored to your specific requirements

Contact

For questions and advice, please feel free to contact VALCO Customer Service. You can reach us by phone or write us an e-mail with the requirement profile for your dust collector. You can also contact a VALCO representative directly.