Cartridge filter

For dry and free-flowing dusts

VALCO cartridge filter systems are characterized by:

Effective extraction and high separation efficiency

High energy saving potential

Complete systems tailored to your requirements

Robust construction

Long filter life

Effective and efficient cartridge filters for optimum dust removal

Cartridge filters are characterized by the fact that the largest possible filter area can be realized in a small space by means of pleats and lamellas. Handling is simple, which makes replacement a short routine job. The air to be cleaned is picked up via the capture elements and cleaned in the cartridge filter. The dusts are collected in a 50-liter dust collection bin, which is equipped with casters for easy transport.

Innovative and customized solutions for filter systems

VALCO is one of the leading manufacturers of filter systems for almost all industrial sectors. In addition to a standard filter program, we also offer cartridge filters according to individual customer requirements and installation conditions. Whether for the filtration of small air volumes as well as large air volumes up to 300,000 m³/h – our cartridge filters are available in various designs. All filter units can be fully customized and planned to meet your needs. VALCO filter units are also available for outdoor installation.

VALCO cartridge filters have filter cartridges with filter materials made of PE or PE-Ce of filter class M as standard. Depending on the application and dust type, other filter media are also used, for example filter cartridges with PTFE membrane or in antistatic design. If required, a second after-filter stage, e.g. H14, can be installed by means of an integrated after-filter.

All filter units can be equipped with various discharge systems. Thus, discharge via rotary valve, screw conveyors, double discharge flaps, etc. is possible. Dust can be discharged into dust buckets on rollers, big bags, standard drums, containers and other receptacles.

VALCO stands for careful design and planning of the entire plant, including piping, acquisition elements, installation and commissioning of all plant components. Extraction hoods, extraction arms or extraction tables, including the piping, electrical wiring and control system, serve as detection elements.

For which applications are VALCO cartridge filters suitable?

Cartridge filters are used for dry and free-flowing dusts found in the chemical, pharmaceutical, metal and plastics industries. Especially in the metalworking industry, cartridge filters are effectively used for filtration of grinding dust (aluminum and all steel alloys), welding fumes or smoke generated by laser or flame cutting.

Since our cartridge filters are also ideally suited for high vacuum systems, for example as filters for central industrial vacuum systems up to a negative pressure of 40 kPa (with appropriate design also up to 80 kPa), our high-performance cartridge filters are particularly suitable for dedusting almost all production processes in the industrial sector.

Metalworking

Plastics industry

Welding fumes

Flame cutting systems

Chemical/pharmaceutical industry

Grinding dust

For shot blasting machines

Foundry Equipment

VALCO cartridge filter in robust design and state of the art technology

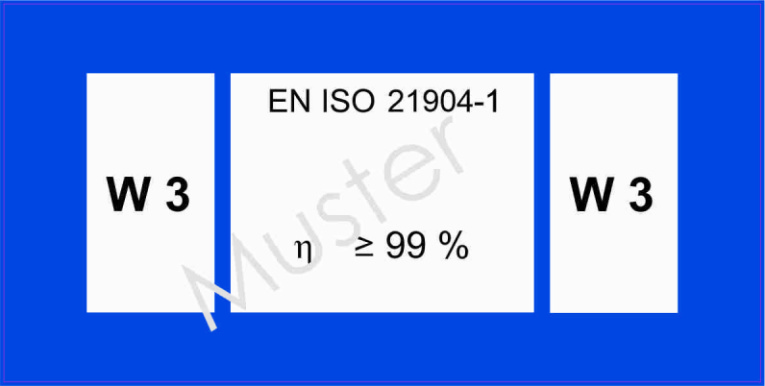

The fully welded construction of our filter units made of 3 millimeter thick sheet steel guarantees optimum tightness and stability for many years. Our cartridge filters comply with the international standard DIN EN ISO 15012-1 (occupational health and safety in welding and allied processes) without testing or individual approval and are marked with welding fume class W3 in accordance with the standard.

All filter units can be offered as special or ATEX versions for explosive dusts.

Our cartridge filters at a glance:

Cartridge filters RX-4500 / RX-5500

Cartridge filters type RX-4500 and RX-5500 are compact cartridge filters with hanging filter cartridges in square design.

RX-7500 / RX-7500 XL cartridge filter

Compact cartridge filters in round design, with suspended filter cartridges.

RX-7500 XL has longer filter cartridges, which results in a higher filter area.

Cartridge filter Pidclean 32

Compact cartridge filter in square design with with 9 hanging filter cartridges.

Optimal for light dusts, such as plastic or wood.

Cartridge filter SAX

Cartridge filter in angular design with horizontally installed filter cartridges.

Compact design with large filter area and very efficient filter cleaning.

Cartridge filter X-Jumbo

Cartridge filter in square design with horizontally installed filter cartridges.

Two filter cartridges are used per filter chamber.

This results in a lower overall height and compared to SAX filter systems.

Cartridge filter XXL

Cartridge filter in angular design with horizontally installed filter cartridges.

Three SAX filter cartridges are used per filter chamber. This results in a lower overall height compared to SAX and X-Jumbo systems.

Engineering of complete plants

Tailored to your specific requirements

Particularly low maintenance & long service life

One of the quality features of our cartridge filters is the special consideration given to maintenance requirements. All our cartridge filters have pre-separation integrated into the side of the filter housing. Coarse particles are dynamically separated via an S-baffle and thus pass directly into the discharge. This provides better protection for the filter elements, allowing for a longer service life. Automatic filter cleaning of the filter elements is differential pressure controlled using compressed air by our efficient, maintenance-free R-Jet cleaning system. Also in the planning phase, we pay special attention to a long service life in addition to the effectiveness of the extraction system.

Energy saving through our cartridge filters

Due to their high filtration efficiency, all our cartridge filters are also suitable for recirculating air operation.

In addition, we usually supply our equipment with frequency converter. This allows fully automatic or manual adaptation of the suction power to the changing production conditions.

Additional after-filters to achieve higher collection efficiencies (e.g. with HEPA HEPA filters of filter class H14 and higher) can be included in the design and supplied.

In addition, we also plan and supply heat recovery systems if required. We will be happy to illustrate the high energy-saving potential by calculating ventilation heat losses.

Our maintenance service

After installation, acceptance and commissioning of VALCO extraction and filtration systems, we are also happy to offer you further service and maintenance services.

Our experienced service staff will be happy to carry out the legally required annual inspection of the filter system and extraction equipment, even for third-party brands.

Contact

For questions and advice, please feel free to contact VALCO Customer Service. You can reach us by phone or write us an e-mail with the requirement profile for your dust collector. You can also contact a VALCO representative directly.