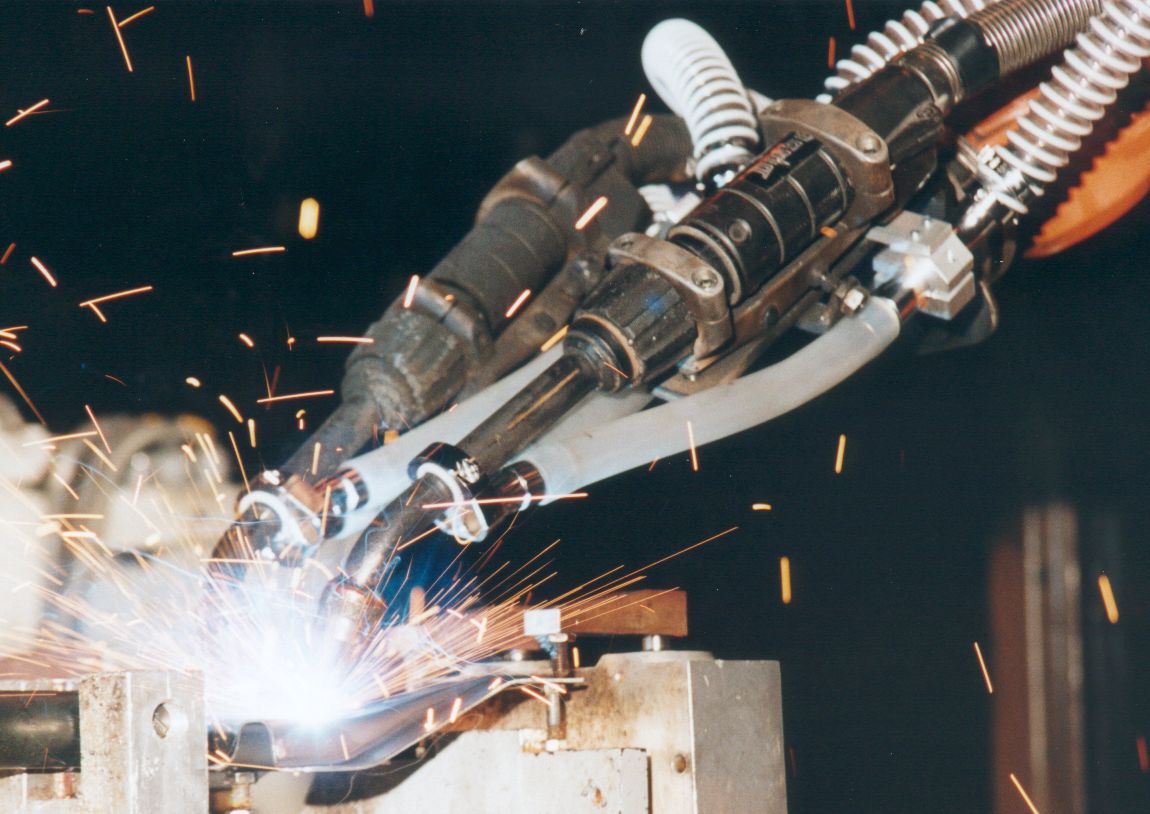

Robot extraction ROPAS

Efficient smoke extraction directly at the torch for welding robots

Direct is simply better.

Direct extraction by means of high vacuum at the torch has been on the market for several years. However, it has nowhere near the notoriety it deserves.

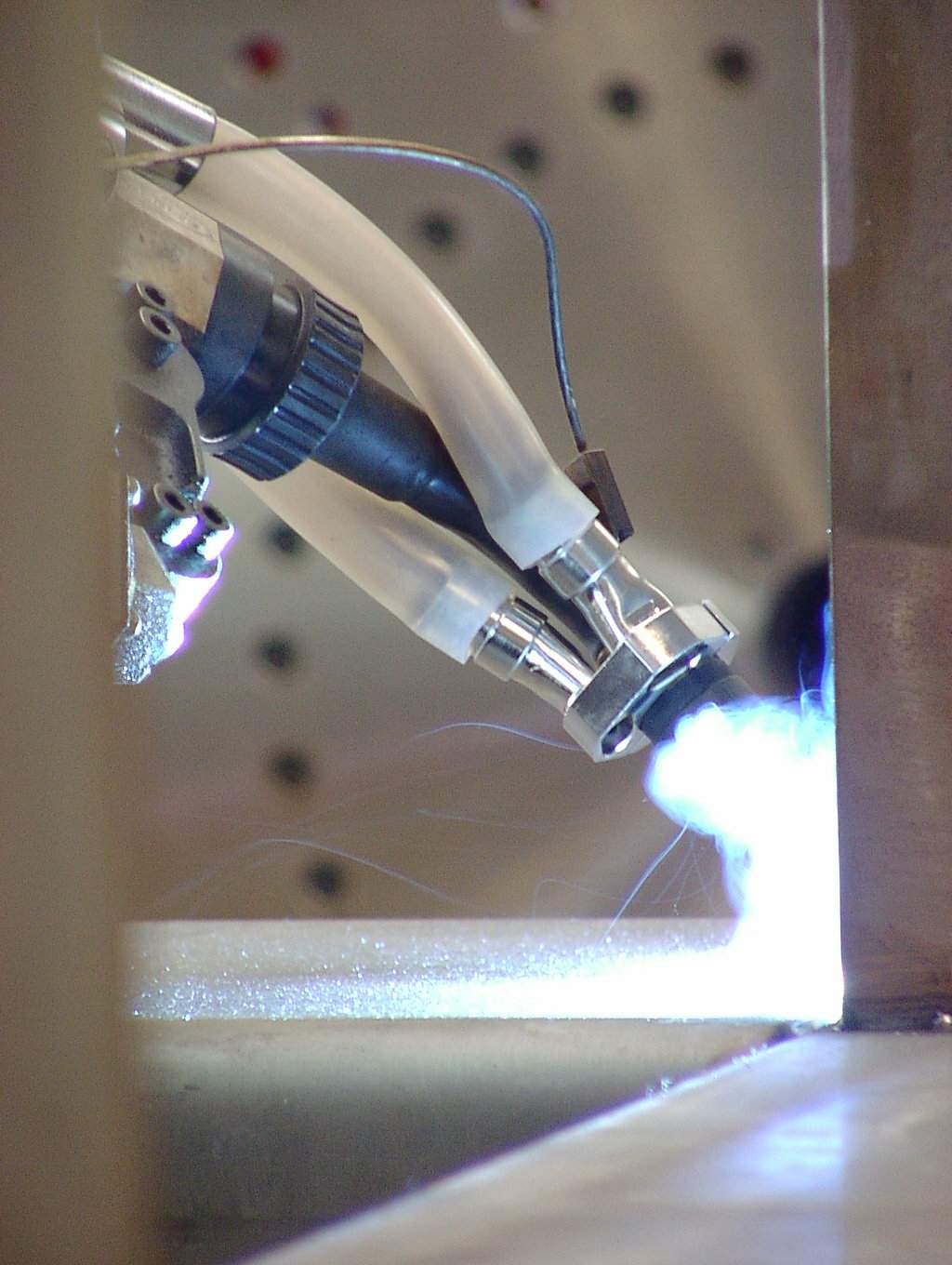

High-vacuum technology makes it possible to place small extraction nozzles directly behind the torch, which are particularly effective at extracting welding fumes. The shielding gas is not affected in this process. Due to the compact and lightweight design, the degree of movement of the robots is not restricted and accessibility to complex workpieces is also given.

Another advantage over conventional extraction hoods comes into play with the piping. With centralized extraction, pipes with a much smaller diameter can be used. If you decide on a decentralized extraction system, i.e. you take a small extraction unit for each robot, there is no need for any piping. The compact suction unit is simply placed close to the robot and connected to the ROPAS system with a suction hose.

One problem that is always encountered with the common canopies of welding workstations is the severely limited accessibility from above. This can lead to the use of crane systems being dispensed with in the case of complete encapsulation. This is reliably avoided with ROPAS point suction, as are the strong air currents that occur with large systems. These are not only perceived as annoying by the employees, but also lead to heat losses in exhaust air operation due to the high air volumes, which leads to higher additional heating costs in winter.

Hoods are also at a disadvantage when it comes to the effectiveness of extraction; since they hang relatively high, the extraction power is limited. In addition, thermal currents often create cross currents that contribute to some of the smoke bypassing the exhaust hood and dispersing throughout the hall. This often requires a complete enclosure, which leads to higher investment costs.

One point that is often raised by opponents of direct extraction is the issue of after-smoke. Particularly with heavily oiled components, the last welded seam smokes afterward while the robot is already working on the next spot. In fact, the after-smoke is subjectively perceived as more disturbing than it actually is. Solid dirt particles are generated only during welding and are captured up to 90% and more by the detection. After-smoke, on the other hand, is produced when small amounts of oil residue on the workpiece evaporate and represents a negligible percentage of the total smoke.

Our patented extraction system ROPAS, for mechanized welding, has proven itself over the years in many welding-intensive operations.

Due to our cooperation with manufacturers of welding robots and our continuous development, we can offer individually shaped fume capture elements for all common robot and machine welding torches. We supply complete solutions from mobile extraction units to stationary systems, including piping and installation.

The advantages at a glance:

Easy-to-use, modular, low-cost system

Very good smoke detection

Can be retrofitted to burners from a wide range of manufacturers

Low cleaning and maintenance requirements

What are the disadvantages of extraction hoods for welding robots?

One disadvantage of extraction hoods for welding robots is that they are highly dependent on the thermal properties of the welding fumes. Halfway up, the smoke often “runs out of breath”. The heavy components fall to the ground and contaminate the machines. They are also highly susceptible to cross currents. High air volumes are needed for reasonably proper functioning. These air volumes in turn lead to high energy losses in winter during exhaust air operation, but they also contribute to high energy and filter costs during recirculation operation.

Is there also a spot extraction for manual welding torches?

Yes! Our MAPAS system, which was specially developed for common manual welding torches, has been proven for over 20 years and offers great advantages. Learn more here.

Engineering of complete plants

Tailored to your specific requirements

Contact

For questions and advice, please feel free to contact VALCO Customer Service. You can reach us by phone or write us an e-mail with the requirement profile for your dust collector. You can also contact a VALCO representative directly.