Oil mist separator EAM

Emulsion and oil mist separator for machine tools and grinding machines

We offer the EAM emulsion mist separators in versions 2 to 6. Each model is suitable for exhaust air operation as standard. In addition, the EAM series can be equipped with a HEPA filter stage for recirculation operation. Our units are equipped as standard with multi-stage filtration and a ball valve for emulsion drainage. The long filter service lives are cost-saving because they ensure low maintenance requirements.

Our VALCO emulsion mist separators EAM are designed for an air volume of 2,000 – 20,000 m³/h and are ideally suited for the extraction of machine tools where emulsion mist or oil mist is generated during machining. VALCO supplies fans in various power levels with or without sound insulation. The aggregates can be flanged directly or placed separately.

The filtering of the hazardous substances usually takes place via 3 filter stages. The first filter stage consists of a 50 mm metal knitted insert filter of 600 x 600 mm with self-cleaning effect. About 70 percent of the emulsions are already separated here.

The second filter stage takes place via filter pockets, which are specially designed for high absorption of cooling lubricant emulsions. Due to the constant filtering at the filter pockets, the separated liquid runs downwards. Here, too, long filter service lives are achieved by the self-cleaning effect.

The third stage of filtration is performed by Hepa absolute filters with a separation efficiency of 99.99%. After passing through this filter stage, the cleaned air can be returned to the working chamber without any problems. Easy and quick filter change is possible via large maintenance doors. The separated emulsion collects in the lower part of the filter and is drained via a drain cock or via a siphon.

Features:

Features:

3 stage separation

Low maintenance

Up to 20,000m³/h air volume

Drain cock for easy emulsion drainage

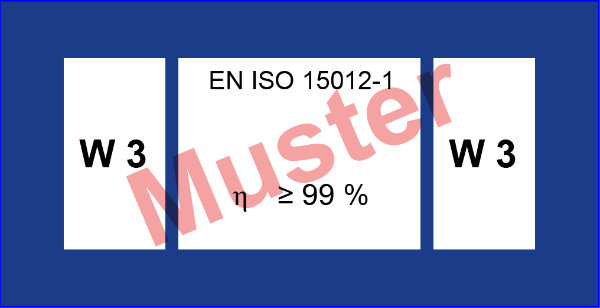

Marks of conformity and certificates

All VALCO cartridge filters comply with the international standard DIN EN ISO 15012-1, thus ensuring occupational health and safety during welding, grinding and related processes. They are permitted without testing or individual approval and are marked with welding fume class W3 in accordance with the standard.

ISO 9001 certified

W3 test mark

Engineering of complete plants

Tailored to your specific requirements

Contact

For questions and advice, please feel free to contact VALCO Customer Service. You can reach us by phone or write us an e-mail with the requirement profile for your dust collector. You can also contact a VALCO representative directly.