Oil mist separator OUK

Emulsion and oil mist separator for machine tools and grinding machines

Our emulsion mist separator OUK is the ideal extraction unit for oil and emulsion mist separation on machine tools and grinding machines. The OUK oil mist separator filters up to 16,000 m³ of air per hour.

The emulsion mist separator OUK is suitable for exhaust air operation and is used wherever emulsion mist or oil mist is generated. For recirculation operation, it must be equipped with an additional HEPA filter stage. The nominal air volume available for the OUK is 16,000 m³/h. Our units are equipped as standard with multi-stage filtration and a ball valve for emulsion drainage. The high filter service lives are cost-saving because they require little maintenance and result in low filter costs.

Oil mist separators prevent health hazards due to inhalation of toxic substances, as the oil and emulsion mists are captured and extracted directly at the point of origin. The suction power can be adjusted on the elements to be operated. After flowing through the multi-stage filters, the clean air is returned to the working chamber. For the separation of harmful gases or solvent vapors, etc., an activated carbon stage can be supplied as an accessory.

Features:

Features:

3 stage separation

Optional HEPA and activated carbon filters

Up to 16,000m³/h air volume

Drain cock for easy emulsion drainage

Technical data

| OUK 2000 | OUK 12000 | |

|---|---|---|

| Dimensions in mm (HxWxD): | 1850 x 775 x 774 | 2470 x 1116 x 915 |

| Weight: | 185 kg | 400 kg |

| Input / Output Diameter: | ? | 250 mm / 402 mm |

| Painting: | ? | RAL-5010 |

| Air volume: | 1,500 m³/h | 3,000 m³/h |

| Filter area: | 40 m² | 80 m² |

| Filter class: | M | M |

| Number of cartridges: | 1 | 2 |

| Dust container: | Dust bucket | Dust bucket |

| E-connection cleaning: | 230 V, 50 Hz | 230 V, 50 Hz |

| Compressed air connection: | 1 1/2″ | 1 1/2″ |

Marks of conformity and certificates

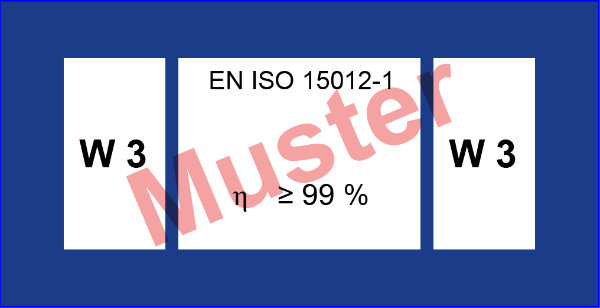

All VALCO cartridge filters comply with the international standard DIN EN ISO 15012-1, thus ensuring occupational health and safety during welding, grinding and related processes. They are permitted without testing or individual approval and are marked with welding fume class W3 in accordance with the standard.

ISO 9001 certified

W3 test mark

Engineering of complete plants

Tailored to your specific requirements

Contact

For questions and advice, please feel free to contact VALCO Customer Service. You can reach us by phone or write us an e-mail with the requirement profile for your dust collector. You can also contact a VALCO representative directly.