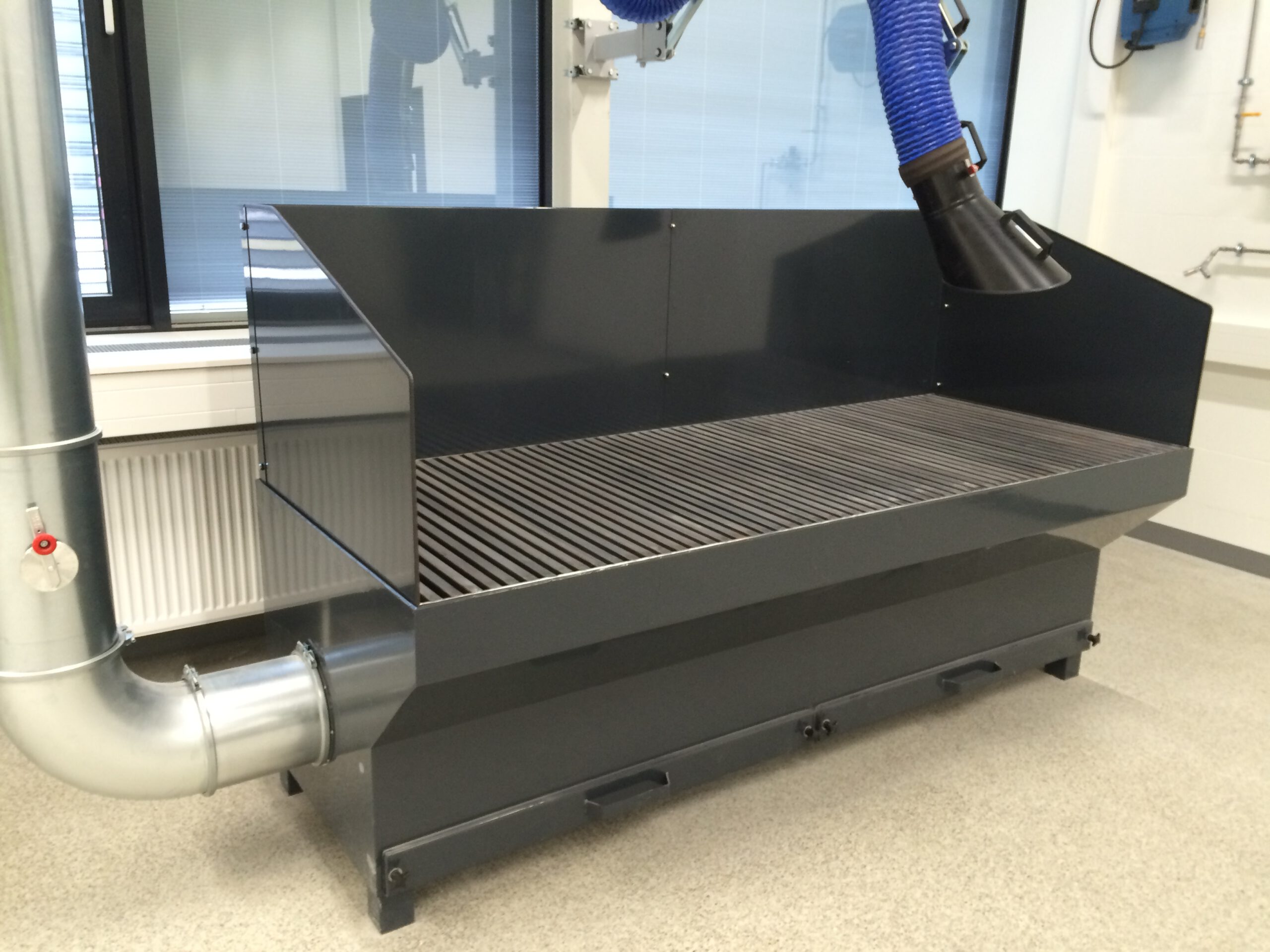

Extraction systems for grinding dust

Extraction of grinding dust at the point of origin

Grinding dust is a health risk! The finer the abrasive, the smaller the dust. The fine dust released is quickly distributed in the room, pollutes the respiratory tract and settles on machines. In addition, sanding dust can cause skin and eye irritation.

In terms of occupational safety and for the satisfaction of your employees, it must be ensured that the dust is extracted and filtered to fall below the permissible dust concentrations if a wet sanding process is not possible. The sanding dust must then be completely captured and extracted at the point of origin if possible.

In addition, some dusts, such as aluminium dust, are combustible and can trigger a dust explosion, endangering the life and limb of your employees and also causing high economic damage. This is particularly the case when there is a high volume of dust in the grinding process and sparks are involved.

These and other points can be worked out as part of your risk assessment.

Grinding work also causes a high level of noise pollution. Therefore, it is often necessary to enclose grinding workplaces in effective noise protection cabins.

Our extraction and filtering systems are ideally suited to effectively capture and extract the dust and, in most cases, return the cleaned air to the room. This means that the limit values can be complied with and clean air can be ensured at the workplace.

We offer

- Various detection elements

- Powerful fans for medium-vacuum and high-vacuum operation

- Effective filter systems with high separation efficiencies

Various systems of explosion protection are also part of our delivery programme. These essentially include the following systems:

- Explosion decoupling

- Explosion pressure relief, even without flames escaping

- Explosion suppression

When extracting grinding dust, it is often unavoidable that sparks are also extracted, which is why we also offer fire protection systems such as spark extinguishing systems.

In addition, you can significantly reduce noise emissions with our individually planned soundproof booths.

Contact us, we will be happy to advise you and find the best solution with you.

Engineering of complete plants

Tailored to your specific requirements

Particularly low maintenance & long service life

One of the quality features of our filter systems is the special consideration of the maintenance effort.All our cartridge filters have a pre-separation integrated into the side of the filter housing. Coarse particles are dynamically separated via an S-baffle and thus pass directly into the discharge. This provides better protection for the filter elements, allowing for a longer service life. Automatic filter cleaning of the filter elements is differential pressure controlled using compressed air by our efficient, maintenance-free R-Jet cleaning system. Also in the planning phase, we pay special attention to a long service life in addition to the effectiveness of the extraction system.

Energy saving through our filter systems

Due to the high filtration efficiency, all our filter units are also suitable for recirculation operation.

In addition, we usually supply our equipment with frequency converter. This allows fully automatic or manual adaptation of the suction power to the changing production conditions.

Additional after-filters to achieve higher collection efficiencies (e.g. with HEPA HEPA filters of filter class H14 and higher) can be included in the design and supplied.

In addition, we also plan and supply heat recovery systems if required. We will be happy to illustrate the high energy-saving potential by calculating ventilation heat losses.

Our maintenance service

After installation, acceptance and commissioning of VALCO extraction and filtration systems, we are also happy to offer you further service and maintenance services.

Our experienced service staff will be happy to carry out the legally required annual inspection of the filter system and extraction equipment, even for third-party brands.

Why can sanding dust be hazardous to health?

Sanding releases fine dust that detaches from the workpiece and the abrasive. The finer the particles, the more risky it is to health. The fine particles can be absorbed through the respiratory tract in the lungs or through the skin and eyes and can cause considerable damage in some cases.

In addition, the health risk also depends on the dust concentration and the material composition. Particular dusts have specific toxic effects. For example, chromium-nickel compounds released during stainless steel grinding are carcinogenic.

Why is the type of collection so important in extraction systems for sanding dust?

The better the collection of the sanding dust, the more effective and efficient the extraction. The technically most effective design is to encapsulate the working area. The distance of the detection element from the point of origin also plays a major role. The closer the detection element is to the point of origin of the grinding dust, the less volume has to be extracted and the more energy-saving the extraction is.

What are the advantages of dry separators compared to wet separators for explosive grinding dust?

When extracting grinding dust, wet separators are sometimes used as a measure for explosion protection. However, with the right design and the right protective components, dry separators, such as cartridge filters or bag filters, can offer the same protection. They require less maintenance than wet separators.

The pressure loss is also lower, so less electrical power is needed at the fan.

In addition, there is no risk of legionella formation in stagnant water.